Bituminous Waterproofing Membranes are now an essential part of the construction industry. Because they keep buildings dry and prevent water from getting in. In this blend of art and science, practitioners use bitumen-based materials to create a waterproof covering. That protects buildings for a long time. We will look at the details of Bituminous Waterproofing Membranes flooring. That breaks the process down into its most essential parts in this complete guide.

Bitumen is a hydrocarbon that comes from crude oil. It makes Bituminous Waterproofing Membranes work. Bitumen is very good at keeping water out. This makes it an excellent material for building protection layers that will last. Some of these membranes may also add polyester or fiberglass to make them more robust and flexible.

Bumper membranes that keep water outcome in two main types:

Polypropylene is added to modify APP membranes. That makes them more resistant to UV light and better at handling high temperatures. On the other hand, SBS membranes receive an addition of a rubber-like material. This makes them more flexible and long-lasting even when it’s cold outside.

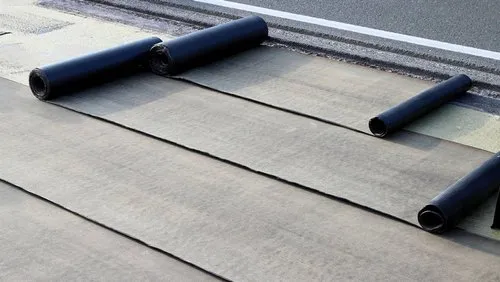

Carefully and precisely apply Bituminous Waterproofing Membrane materials. Depending on product and project needs, install these membranes using a torch, heat-welding, or cold-application methods. Use an open flame to heat the membrane during installation in the case of torch-applied membranes. Fuse the membrane using hot air or an electric current for heat-welded membranes. When adhesives or self-adhesive technology are used in cold-applied membranes, they don’t need to be heated during installation.

Preparing the surface well is the first step to a sound Bituminous Waterproofing Membranes system. That base needs to be clean, dry, and free of anything. That could make it harder for the adhesive to stick. Priming is often necessary to strengthen the bond between the membrane and the material. What primer to use depends on the substrate type and the weather.

Adhering to industry norms and rigorous quality control measures is essential. It ensures that Bituminous Waterproofing Membranes are of high quality and perform effectively. Local building codes and ASTM (American Society for Testing and Materials) standards tell us how to test materials, place them, and what their properties are. Following these rules is very important to ensure the protection system works well and lasts long.

As people become more aware of the environment, the construction business is focusing more and more on environmentally friendly methods. To meet these needs, Bituminous Waterproofing Membranes are changing. These companies are looking into ways to make them more eco-friendly and recycle them. A more environmentally friendly way to build is to use goods. They are made from recycled materials and have little to no environmental effect.