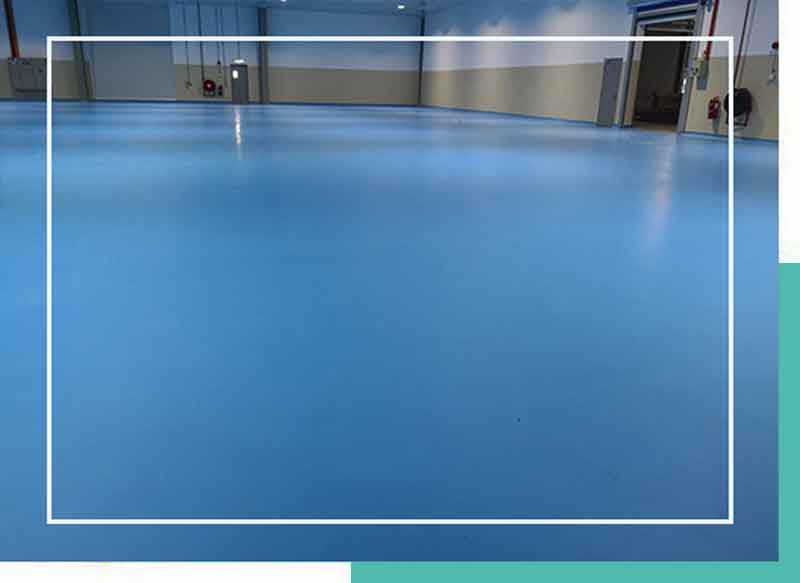

FirstTech is Best Industrial, commercial & Residential and Epoxy Flooring in Bangladesh. We have a reputation for being the best in the business because we always strive for greatness and have a history of happy customers. Because we know a lot about a lot of different uses for epoxy flooring, we are the best choice for people who want floors that will last.

FirstTech has the skills and commitment to meet your specific needs, whether you’re a business owner looking to improve your commercial space, an industrial facility in need of a durable floor, or a homeowner wanting a smooth, easy-to-clean surface. With a focus on quality, customization, and skill, we are the best at installing epoxy floors all over Bangladesh.

Our Polyurethane (PU) flooring solutions offer a seamless blend of durability and aesthetics, providing a versatile choice for different environments.

Explore our epoxy flooring in Bangladesh solutions known for their resilience, longevity, and captivating visual appeal. Ideal for various settings, our epoxy floors are designed to withstand the rigors of daily use.

For a flawlessly even and smooth surface, our self-leveling epoxy flooring in Bangladesh is the perfect choice. It combines functionality with a sleek finish, catering to both practical and aesthetic requirements.

Optimize the strength and durability of your concrete floors with our floor hardener solutions. It ensures a robust and long-lasting surface, even in high-traffic areas.

Our waterproofing solutions provide an effective barrier against water damage, making them an essential choice for areas prone to moisture and humidity.

Explore our comprehensive range of construction chemicals designed to enhance the performance and longevity of your structures.

At First Tech BD, we are proud to offer the best industrial flooring solution. Because these are specifically designed to meet the needs of a wide range of businesses. We are the best choice for businesses that need reliable and cutting-edge flooring solutions. Embark on a journey where advanced technology meets unparalleled expertise, ensuring your industrial floors stand the test of time. First Tech BD: Getting your floors just right.

At First Tech BD, we’re proud to offer a wide range of Diverse Flooring Options. We demonstrate our dedication to providing the best industrial flooring solution through our wide range of products. Crafting with precision, we ensure our diverse range is durable, safe, and tailored to the unique needs of each industry. We at First Tech BD know that one size doesn’t fit all. That’s why we design our wide range of flooring choices to fit your industrial space perfectly.

At First Tech BD, we know that each industrial space has its own needs. That’s why we’re proud to offer Customisation for Specific Needs in our industrial flooring solution. Our team works with clients to create industrial flooring solution. It’s essential to give each client not just a solution, but the right option. First Tech BD is your partner in ensuring your industrial flooring experience is unique and meets all your needs.

FIRSTTECH Being Create Their Brand name in Bangladesh for his Quality. FIRSTTECH has many Experienced Experts Flooring & Construction Chemicals sector in Bangladesh. FIRSTTECH Show Their Best Quality of Products & Application Service. They are not Compromise the Quality issue. Their all types of products is World Class & Branded. They are not Uses Low grade Products. Their all Products is Tested & Certified form International Authorized. They Application their all products as per Methodology Providing by the Manufacture. FIRSTTECH is the one of the Best Flooring & Construction Chemicals Company in Bangladesh.

Commitment is the most Important Subject any service Sector. FIRSTTECH Always Looking best Commitment form their satisfied Customer. FIRSTTECH all time Achieved their goal form his satisfied Clients for committed their working time Schedule. FIRSTTECH Already deals their Many Locally Company ,Govt. Project & Multinational Company & also Handover the project in just time.

FIRSTTECH is the Company Which is composed of a professional or team of experts that deliver work or aid in completing a task for the benefit of its customers. we also committed to great standards of sustainability service for all types of products, services and solutions. By the side of the tools and equipment’s for application, we have full of resource with all types of latest items. Our global standard application processes and all time customer support is our motto. FIRSTTECH all time ready for their best service.

With our Seamless and Hygienic Flooring solutions, First Tech BD raises the bar for industrial flooring. It is clear to us that cleanliness is essential, especially in fields like food and medicine. Our seamless flooring gives you a smooth, nice-looking surface. Our industrial flooring solution choices meet strict industry standards for cleanliness. We at First Tech BD go above and beyond to provide industrial flooring solution that meet.

At First Tech BD, we are dedicated to offering the best industrial flooring solution. Professionals on our team have the skills and understanding to install industrial flooring solution correctly. We go the extra mile by providing complete care services. First Tech BD has the most up-to-date industrial flooring solution.

Our success at First Tech BD is tied closely to the success of our clients. We’re very proud of how our best industrial flooring solution has helped many different types of businesses. Through client success stories, we show how our custom flooring solutions have improved safety, operational efficiency, and general work environment. We’re just interested in making lasting, cutting-edge flooring.

First Tech BD is a leader in industrial flooring solution. Because of it provides a wide range of choices. Those are specifically designed to meet the needs of modern businesses. First Tech BD is dedicated to quality, innovation, and customer satisfaction.

Now let’s talk about epoxy floors. They’re like the superheroes of flooring.Seamless coating that can handle anything life throws at it. That’s epoxy for you – a mix of resins and hardeners that team up to create this indestructible finish on concrete surfaces.

Why is everyone loving epoxy flooring? Well, first off, it’s practically invincible. It laughs in the face of heavy foot traffic, machinery, and even chemical spills. That’s why you find it strutting its stuff in garages, warehouses, and factories – basically, the tough spots.

But it’s not all about muscle – epoxy is a bit of a fashionista too. With a rainbow of colors and finishes to choose from, you can give your space a personalized touch. Fancy a glossy, modern vibe? Epoxy’s got your back. Prefer something more chill? Matte finish, coming right up!

And the best part? It’s like magic – a smooth, seamless application that turns your floor into a breeze to clean. No hiding spots for dirt and germs here! Perfect for kitchens, labs, and anywhere you want to keep things squeaky clean.

Benefit from our use of high-quality materials, ensuring that our flooring solutions stand the test of time, resisting everyday wear and tear with ease.

Our expert team is dedicated to providing professional guidance and support throughout the selection and installation process. We ensure that you receive the perfect flooring solution tailored to your specific space.

At First Tech, we prioritize exceptional customer service, offering a seamless experience from consultation to installation and beyond. Your satisfaction is our utmost priority.

Epoxy flooring has become quite the go-to choice in Bangladesh for all sorts of spaces because it’s like the superhero of floors. Imagine having a floor that can take on anything – chemicals, heavy traffic, you name it. That’s epoxy flooring for you, creating these seamless and super sturdy surfaces that are perfect for busy places like factories, warehouses, garages, and even healthcare spots.

And get this – it’s not just a tough guy. It’s a smart investment too. Lasting long and needing next to no maintenance, epoxy flooring in Bangladesh is like the gift that keeps on giving. As businesses in our awesome country keep growing, epoxy floors are stepping up to the plate, offering a modern and practical solution that’s just what we need for our bustling environments. Cheers to sturdy, stylish floors that can handle anything life throws at them.

Join us in embracing eco-friendly epoxy options designed for environmentally conscious customers. Our sustainable flooring solutions provide an ideal choice for those seeking durability with a minimal environmental footprint.

Looking to jazz up your floors with epoxy paint in Bangladesh? Epoxy floor paint is the go-to choice for its toughness, resistance to chemicals, and that extra touch of style. Now, let’s talk prices – because we all want the best bang for our buck!

In Bangladesh, the cost of epoxy floor paint can be a bit like a menu – it depends on what you’re ordering. Top-notch brands might have a higher price tag. They are known for their quality. On an average, you’re looking at around ৳600 to ৳1500 per liter. Keep in mind that the type of epoxy, whether it’s solvent-based or water-based, and any cool extras like anti-slip features or fast-drying magic can influence the price.

Consider your floor’s needs – is it a high-traffic area? Do you want something quick-drying? These factors matter. And, since prices can change, it’s a good idea to check in with your local suppliers, hardware stores, or epoxy experts for the latest and greatest pricing info. Time to make your floors shine.

First Tech BD using world best German technology and raw materials. Formulation customized it local weather and environments. Own R&D and concrete lab help striving for excellence.

How much 3D concrete flooring is worth depends on how long it lasts and how strong it is. It would cost more to buy high-quality epoxy floor supplies. On average, installing a 3D concrete floor costs between 400 and 500 taka per square foot. A complicated style would take a lot of work and cost more to install.

Yes, epoxy flooring is waterproof. Its seamless and non-porous surface prevents water from seeping through, making it an excellent choice for areas prone to moisture or spills, such as basements, kitchens, and bathrooms.

Between 10 and 20 years

How long a concrete floor system lasts depends on how thick it is, how often it is used, and how well it is taken care of. Most epoxy floors last between 10 and 20 years, which is much longer than a finished concrete floor, which will chip and wear quickly in high-traffic areas.

Once the epoxy floor has fully hardened, the material is no longer dangerous to health. The only time epoxy could be dangerous is if you sand the floor after it has set and then breathe in the dust that comes off of it. To have a beautiful floor that lasts, it’s important to choose the right material and have it put in the right way.

Durability of Tiles vs Epoxy

Since the firing process makes tiles hard and tough, they are usually immune to scratches and scuffs. However, they can crack or chip when hit very hard. Epoxy is more resistant to strong hits because it is softer and more like a resin. However, it is easily scratched and scuffed.

Epoxy is More Durable

In fact, epoxy floors can last up to 20 years on average. Also, epoxy is much easier to clean than concrete, so it requires very little upkeep. Epoxy flooring is also resistant to germs and bacteria, which makes it a better choice for places like hospitals.

The epoxy floor covering is very clean. Epoxy resin floors are easy to clean and sweep because not much sticks to them. It doesn’t let bacteria and germs grow on it, which makes it easy to clean. It doesn’t smell bad and doesn’t change the taste of food, so it’s great for food processing plants and industrial kitchens.